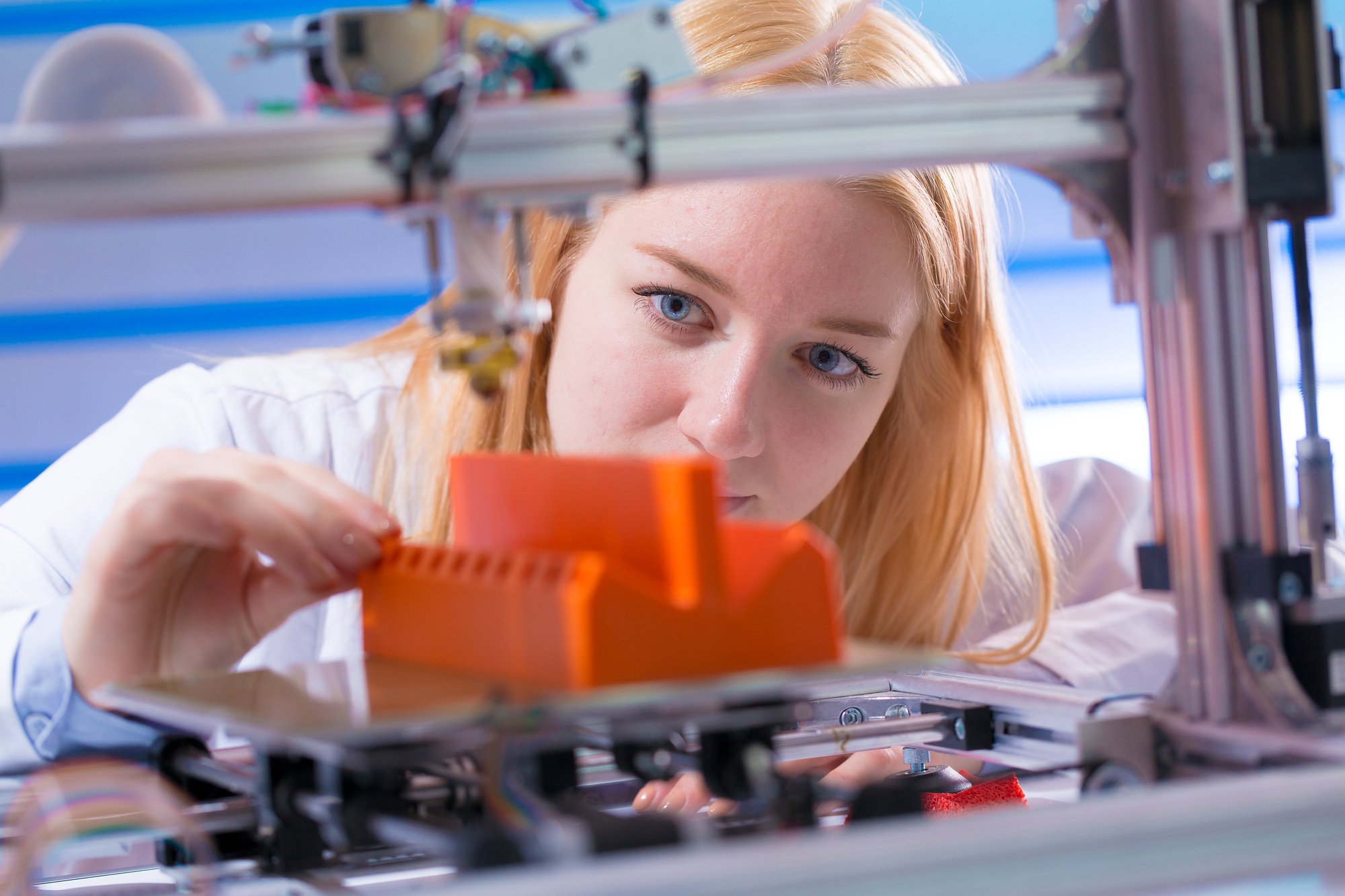

3D Printing Solutions for Fast Prototyping and Product Growth

For those that are thinking about a modification in their organization, 3D printing software program is a superb alternative. This software program is produced computer system use only as well as not for use by common people. They function by supplying details of objects that need to be duplicated in 3 dimensions using one of the most sophisticated technology. The object can be scanned right into the equipment prior to the 3D printing procedure happens. This enables the customer to obtain the perfect shape of the things.

Rapid prototyping is a principle which makes use of liquid steel parts in order to create models of an object which can after that be given the manufacturing stage. It is among the most effective methods of creating items as it permits quick growth of new layouts with no significant loss of quality. Companies which use this approach will require 3d printing options in order to produce prototypes that can be made use of for testing functions.

As a whole, there are 2 sort of additive production technologies offered - solid-state and also liquid-state. Solid-state 3D printing modern technologies utilize strong color powder instead of liquid metal in order to develop the things. This is a relatively more recent kind of additive manufacturing as well as is being progressively used by several makers. The process works well with plastics as well as steels in addition to porcelains. On the other hand, liquid-state 3D printing modern technologies use an electric present in place of a strong color powder in order to create the things. The benefit of this kind of technology is that it gives much more adaptable alternatives in terms of style freedom.

It can be adjusted to fulfill any manufacturing requirement, whether it is quick prototyping or full manufacturing quality parts. Moreover, business can integrate this process with other manufacturing procedures in order to eliminate lengthy lead times. This is particularly relevant for little as well as medium-sized makers that have actually limited abilities but still call for a quick prototype produced in a brief time period. One such example is a new item that is presently being created using cad modern technology. Since additive production permits quick prototyping to be done on huge volumes of components, firms have the ability to reduce manufacturing costs as well as consequently enhance their revenue margins. This is because the item is currently being made in huge quantities while the advancement procedure is being completed.

Additionally, the additive manufacturing process enables makers to rapidly establish model parts or full manufacturing runs without needing to wait for complete manufacturing. Due to the fact that each specific layer in the cad file is useful in comparison to the one below it, the whole picture of the things can be produced extremely promptly. This causes lowered waste, raised versatility, price financial savings and also better worker relationships. additive manufacturing innovation provides a variety of distinct benefits, especially when it involves the quick advancement of brand-new item models. You can visit this website for more details - goengineer.com

Click this link for more info - https://www.britannica.com/technology/3D-printing